Steel slag is a by-product of the production of iron and steel, which consists of slag making materials, smelting reactants, eroded and fallen furnace bodies, materials, impurities brought in by metal furnace materials and slag making materials specially added to adjust the properties of steel slag.

Due to the new and higher technical requirements for the properties and quality of concrete put forward by the modern engineering construction industry, the steel slag active mineral fine admixture has attracted more and more attention in the field of materials and engineering abroad, even called the sixth component of concrete. However, as a by-product of industry, the quality of steel slag can not be fully guaranteed. Chloride ions in steel slag can cause corrosion of steel bars in concrete and damage the durability of concrete. At present, the standard GB175-2007 "General Portland Cement" has been issued, which limits the content of chloride ion in cement, and stipulates that the content of chloride in cement is less than or equal to 0.06%.

Determination of halogen in steel slag

In this experiment, the high temperature hydrolysis- ion chromatography method is used. The pretreatment process is simple. Only one sample injection is needed for determination. It has high automation, high accuracy, good reproducibility and simple detection method. It can determine the content of fluorine and chlorine at the same time.

Grind the sample to a particle size of no more than 0.080mm, dry the sieved sample in an oven at 105 ℃± 2 ℃ for 1h, take it out and cool it in a dryer to room temperature for standby.

Weigh 70mg of the sample, spread it into the quartz boat, automatically enter the on-line combustion ion chromatography system for analysis according to the set procedure, and absorb the gas generated after high-temperature cracking with 10ml of sodium hydroxide solution. Then test according to the condition of ion chromatography. At least 2 times of empty firing of quartz boat is required before sample combustion.

Chromatographic conditions

Instrument: CIC-D150

Column: SH-AP-1

Eluent: 15mM KOH

Flow rate: 0.8 mL / min

Column pressure: 9.7Mpa

Detection method: suppressed conductivity method

Injection volume: 25uL

Suppression current: 50 mA

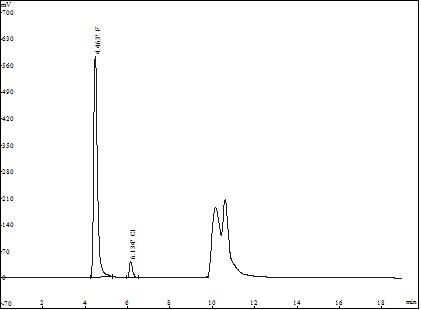

Chromatogram