The conductive adhesive can be bonded at a suitable curing temperature, which is much lower than the temperature of 200 ℃ of tin lead welding, so as to avoid material deformation and thermal damage of electronic devices caused by high welding temperature. At the same time, the conductive adhesive can be made into slurry to achieve a high linear resolution, and the process is simple and easy to operate, which can improve the production efficiency and avoid environmental pollution caused by heavy metal lead in tin lead solder. Therefore, the conductive adhesive is an ideal alternative to lead tin welding to achieve conductive connection.

Conductive silver adhesive is a kind of adhesive with certain conductivity after curing or drying. Usually its main components are matrix resin and conductive filler, namely conductive particles. Through the bonding effect of matrix resin, conductive particles are combined together to form a conductive path and realize the conductive connection of the bonded material.

1.Harm of halogen compounds

In recent years, with the deepening of some scientific research, halogen compounds have been widely concerned because of the following hazards: persistent organic pollutants (POPs) containing halogen; organic solvents containing halogen are ozone depleting substances (ODS); plastic containing halogen will release hydrogen halide (HCl, HBr, etc.) when meeting high temperature, and form acid mist when meeting water vapor in the air; halogen containing compounds When the plastic burns, it produces dioxin, which is a high accumulation and long-lasting carcinogen; when the halogen containing plastic burns, it will produce a large number of thick smoke, which will reduce the visibility and affect the identification of escape routes. Currently, the international requirements for halogen-free are mainly related to chlorine and bromine.

Conductive silver adhesive is widely used in electronic appliances. In order to control the total amount of halogen in electronic appliances, it is necessary to measure the chloride ion content in conductive silver adhesive. It is specified in IEC61249-2-21:2003 for printed circuit board. The specific requirements are: bromine < 0.09% (900 ppm), chlorine < 0.09% (900 ppm), total halogen < 1500 ppm.

2.Detection of chloride ion in conductive silver adhesive

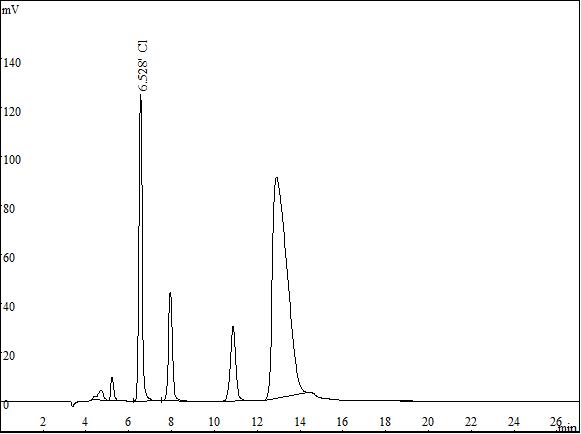

In order to determine the chloride content in the conductive silver adhesive, the sample was pretreated by the oxygen bomb combustion method, and the halogen compound after combustion was absorbed by the absorption solution. After passing the absorption solution through the H column and the 0.22μM filter membrane, the sample was analyzed by CIC-D150 ion chromatograph, and the chloride content in the sample was determined. At the same time, the control group experiment of the quantitative filter paper (3*1.5cm) was carried out.

Instrument: CIC-D150

Column: SH-AC-11

Eluent: 13 mmol / L KOH (EG)

Flow rate: 1.0 mlL/ min

Detection mode: suppressed conductivity method

Injection volume: 25uL